I’m a glutton for punishment and have decided to upscale my existing FatScreen mod idea. The last time it took 27 attempts to get right, I’m hoping it’ll be easier this time (He said confidently!)

I’m using an 8″ IPS screen and a Portavision 7″ I scored last second for cheap on eBay and plan to combine them into something with a lovely curved screen.

The screen I’m using doesn’t have RGB in so I’ll use a GBS 8200 board modded with GBSControl, the original units are a bit pants but with the GBSControl mod, they’re pretty good.

To upscale this, I needed to make a lens that is way bigger than I have ever made before, I always try to do the hardest part of any project first and the lens is very definitely the hardest part!

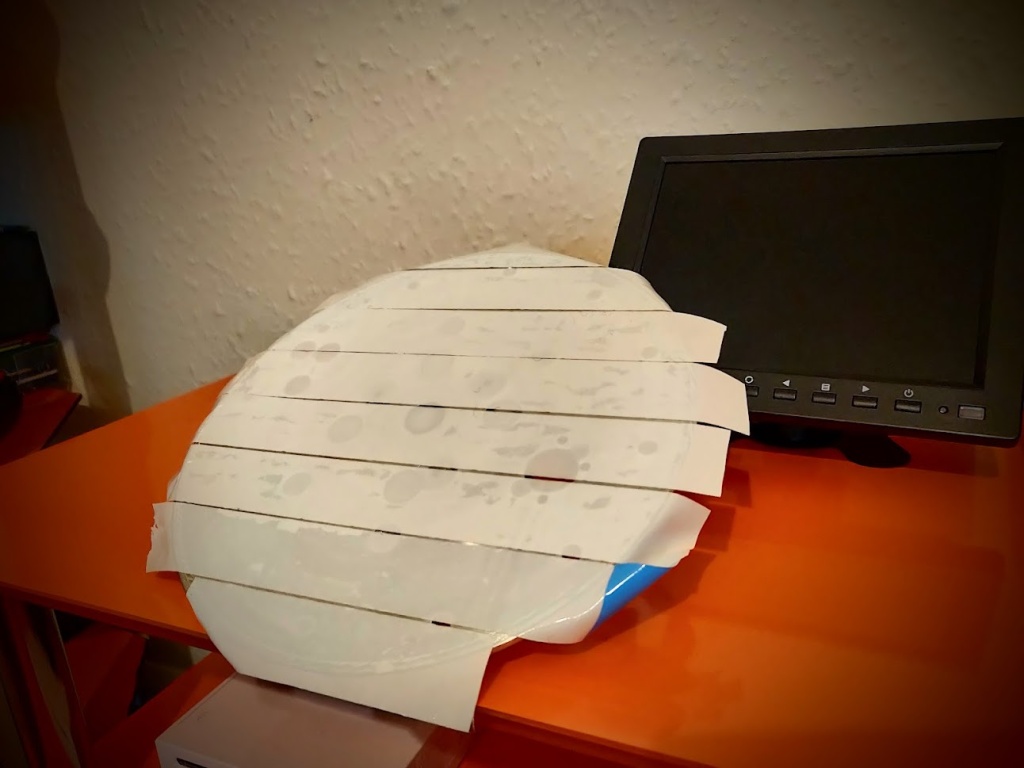

I’ve used a decent chunk of Perspex for this which I needed to cut and shape into a lens, this is A) Difficult. and B) Disaster prone. Perspex is a moody beast but if I can get the lens made, I’m over one of the hardest parts!

250 x 250 x 25 – That’s big!

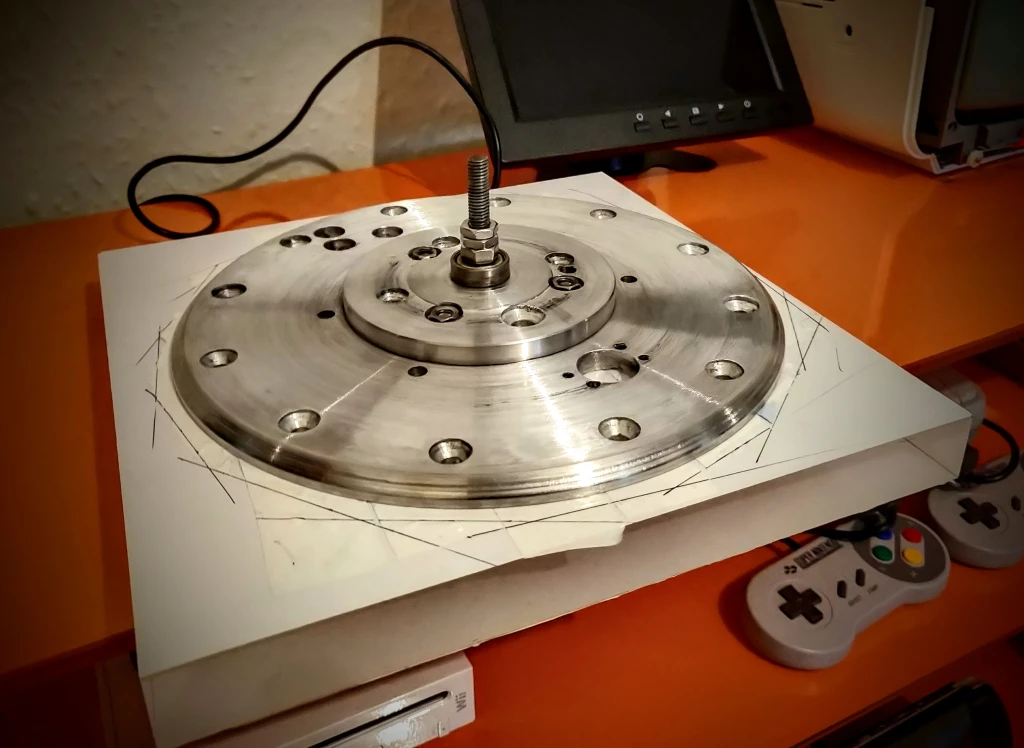

I’ve made a large arbour to bond the Perspex to for machining as there’s no other way to put it onto my lathe.

Well that’s a honking great arbour!

I’ll use double sided thermal tape to hold it onto the arbour, it won’t come off in a hurry and may not even come off when I need it to!

I’ve designed the arbour to spin on a shaft, this’ll help with final shaping of the lens on a ‘slightly modified’ Belt sander.

I’ve roughly cut the shape out before putting it in the lathe, knocking those corners off is likely to go Donkdonkdonkdonkdonkcrack!

It was tense turning the lathe on with this in place for the first time, so much scope for disaster! I got it rounded off nicely though.

I gave the lens a rough shaping to map out the curve next. My lathe tools are for metal so it’s hard going. I tried something new, and thought I’d try it by hand with a chisel, I now know this to have been a monumentally stupid idea.

It was all going well until ‘something’ caught. It all happened so quickly that I still don’t know what went wrong. At the time, I slapped the shut off switch for the lathe really quickly as my hand got dragged in too.

I sat in shock, holding my hand which hurt like buggery. I was holding one hand in the other and eventually took a quick peek at my hand to inspect the damage (A bit of a Schrodinger’s injury, I couldn’t tell if I was injured until I looked)

Luckily my hands are quite bendy so I got away with some scrapes and bruising. It was definitely a warning to be more careful (and less of an idiot!)

Thankfully, the Perspex was way oversized so it was recoverable – Phew!

The lathe tool needed to go, it started smooshing the plastic down onto the piece instead of cutting it and was taking forever.

I ground a tool specifically for Perspex out of an old knackered bit, Much better! I can start making some serious progress! Having just X and Y to work with is a bit like drawing a circle with an Etch-a-Sketch but doable!

To finish the rough curve, I used a bendy ruler and rubbed it against the Perspex to get the right shape, it marked the high spots nicely. It took a few goes at marking, then machining off the high spots but the shape was getting there.

I took the platen out of my belt sander to get the curve I needed, it worked so well that I had the right shape in just under an hour.

After belt sanding, I got a lovely curve!

I needed to check the geometry so gave it a quick buff, it turned out perfectly!

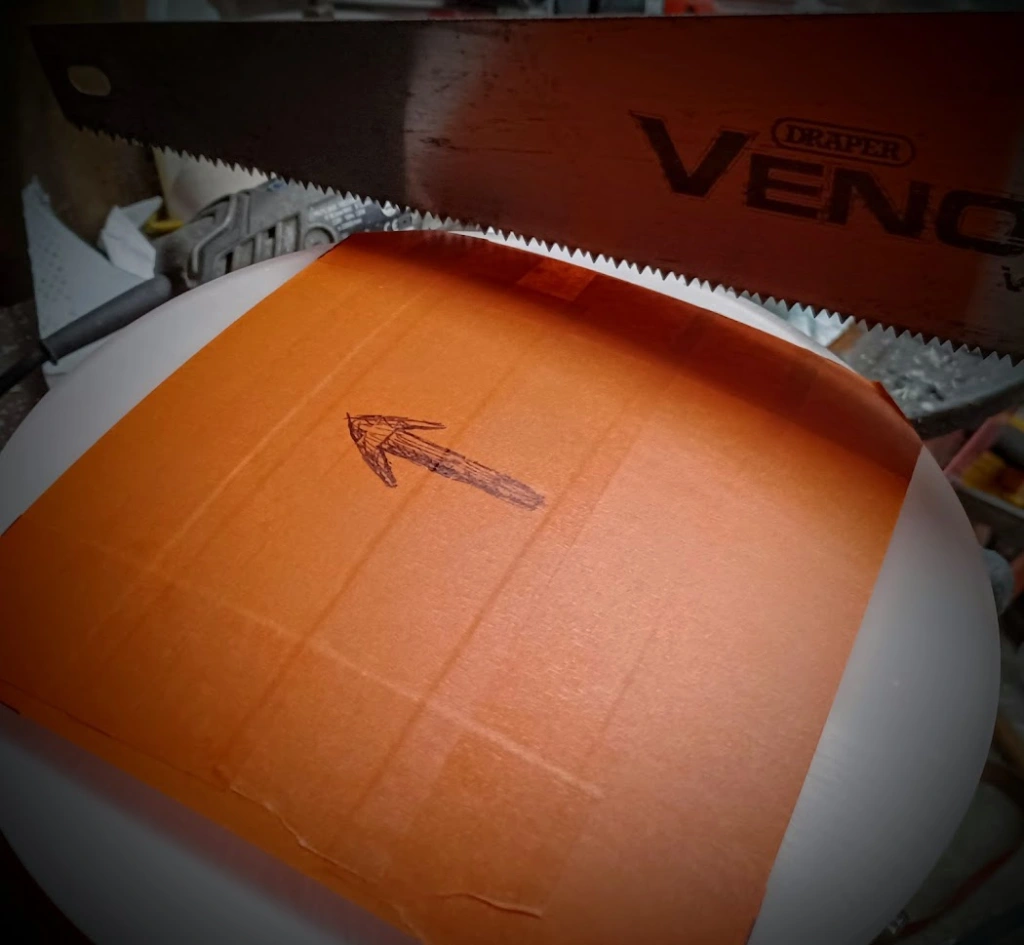

Now the geometry was right, I needed to cut and shape the lens to the shell. Yes, that’s a wood saw!

The lens is roughly cut and shaped but needs a final fettle and polish. It’s a little oversized but it’ll shrink after final sanding and polishing.

Final polish done, lens complete!

In the next part, I’ll be prepping the shell and crafting a new Bezel. I still don’t know if any of this will work as intended but I’m going to push on and find out. 🙂